CJ Main Equipment

As an expert manufacturer, CJ Industry provides high-quality Custom CNC Metal Spinning solutions to enhance your production efficiency and precision.

Metal Laser Cutting Machine

CJ delivers precision cutting solutions with our advanced equipment portfolio: Two Prima Power 5-Axis Laser Systems featuring dual-cell work envelopes (X: 161″/4090mm, Y: 82″/2080mm, Z: 38″/965mm), a 10kW fiber laser for rapid 20mm carbon steel processing, a 4kW laser for intricate contours, paired with two 5-axis waterjets (cold-cutting technology) and a plasma cell handling up to 60mm thick plates. Our automation team optimizes production through dynamic nesting algorithms, achieving 27% material efficiency gains, 35% faster multi-process workflows, and ±0.1mm 3D positioning accuracy across DIN/ISO/ASTM-certified operations for titanium, carbon steel, and composites.

Plate Rolling Machine

our advanced plate rolling machines are engineered to deliver exceptional accuracy and versatility in transforming flat metal sheets into high-quality cylindrical components. Designed for efficiency and precision, our equipment handles a diverse range of materials, including carbon steel, stainless steel, aluminum alloys, and more

CNC Spinning Machine

Leading CNC metal spinning lathes merge tradition with precision, revolutionizing metal forming with programmable accuracy, rapid production, and superior finishes to meet stringent tolerances, enhancing operational efficiency.

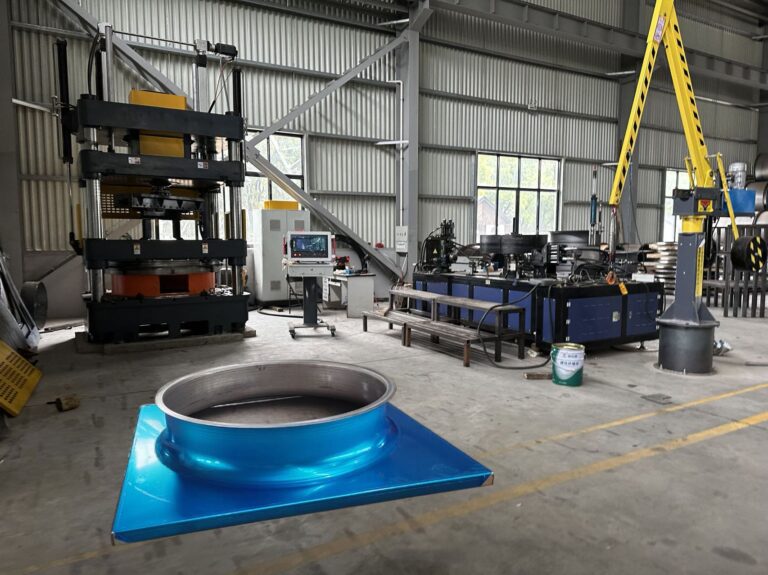

Heavy-Duty Spinning & Flanging Machine

Engineered for industrial precision, our robust machine handles steel ducts, cones, and plates up to 3000mm (118″) diameter and 15mm (0.6″) thickness – ideal for axial and centrifugal fan components. Featuring a high-accuracy punching system, it ensures seamless production of complex shapes while boosting throughput

CNC Flanging Machine

Advanced CNC Axial Fan Flanging for top-quality flanges, reinforced with precision holes, bell mouths, and inlet cones for cylindrical ducts and axial fan casings. Handles up to 2050mm diameter, 10mm steel for consistent, high-volume production.

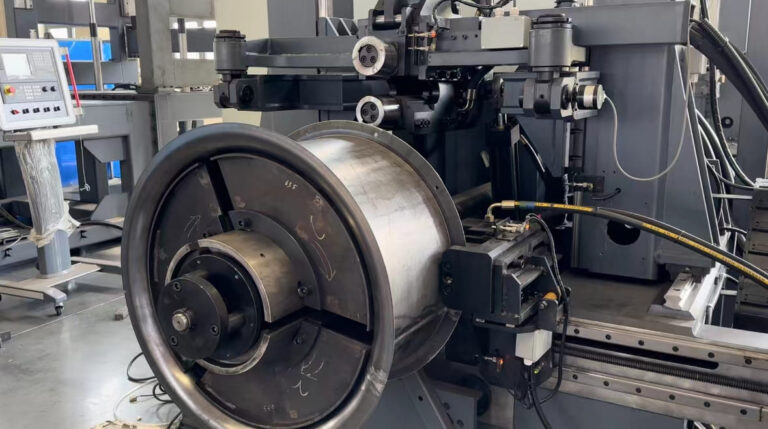

3-Wheel CNC Power Spinning Machine

This equipment is a horizontal three – wheel CNC power spinning machine. It is mainly used for the power spinning forming of variable – wall – thickness cylindrical parts made of common carbon steel, aluminum alloy, stainless steel, alloy steel, etc. It is widely applied in the production fields of automobiles, chemical industry, aerospace, military industry and so on.

Inner Spinning Machine

Our vertical inner spinning machine is engineered for precision flanging of outlets, air conditioner components, and custom panels on both square and rectangular sheets. Designed to enhance manufacturing efficiency, it handles materials up to 1500mm (59″) wide and processes holes up to 1200mm (47″) in diameter, ensuring seamless integration into your production line.

Finishing

At CJ, we are committed to delivering top-quality finishing solutions that surpass customer expectations. Our advanced finishing line features dual manual and automatic powder coating guns, capable of handling parts up to 4’ x 6’ x 10’ (1220mm x 1830mm x 3050mm). Additionally, our e-coat department is equipped with large batch dip systems, accommodating parts up to 42” x 46” x 85” (1067mm x 1168mm x 2160mm)